When I started 3D printing, bulging corners frustrated me a lot. They happen because of sharp turns, speed, or cooling issues. After learning and tweaking settings, I fixed them. Don’t worry—it’s common, and you can solve it too!

3d printer bulging corners ( short answer)

3D printer bulging corners occur due to sharp turns, incorrect speed, or cooling issues during printing. Adjusting acceleration settings, improving cooling, and fine-tuning your slicer can help fix this common problem for smoother prints.

In this article we will discuss 3d printer bulging corners.

What Are 3D Printer Bulging Corners?

3D printer bulging corners are rounded or swollen edges that appear on prints, especially at sharp turns or corners. This happens because the printer slows down at corners, causing extra material to build up.

Common reasons include incorrect speed settings, poor cooling, or slicer issues. These bulges can make prints look uneven or messy. To fix this, you can adjust the acceleration, optimize cooling, and fine-tune Cura slicer settings to create smoother, cleaner edges on your 3D prints.

Why Do the Corners of My 3D Print Curl Up?

Corners of your 3D print curl up when the material cools too quickly, causing it to contract and lift from the print bed. This issue is more common with materials like ABS. To prevent curling, ensure your print bed is heated to the right temperature and use adhesives like glue or tape to improve adhesion.

You can also reduce cooling fan speed, which allows the material to cool more evenly. Lowering print speed for better layer bonding also helps prevent this issue.

Causes of Bulging Corners in 3D Prints – Improve Print Accuracy!

1. Excessive Heat and Retraction Settings

Bulging corners often occur due to excessive material deposition or heat buildup. When the printer decelerates at corners, the nozzle lingers longer, causing more filament to ooze out and accumulate. This localized overheating can make the plastic flow more than desired, leading to swelling.

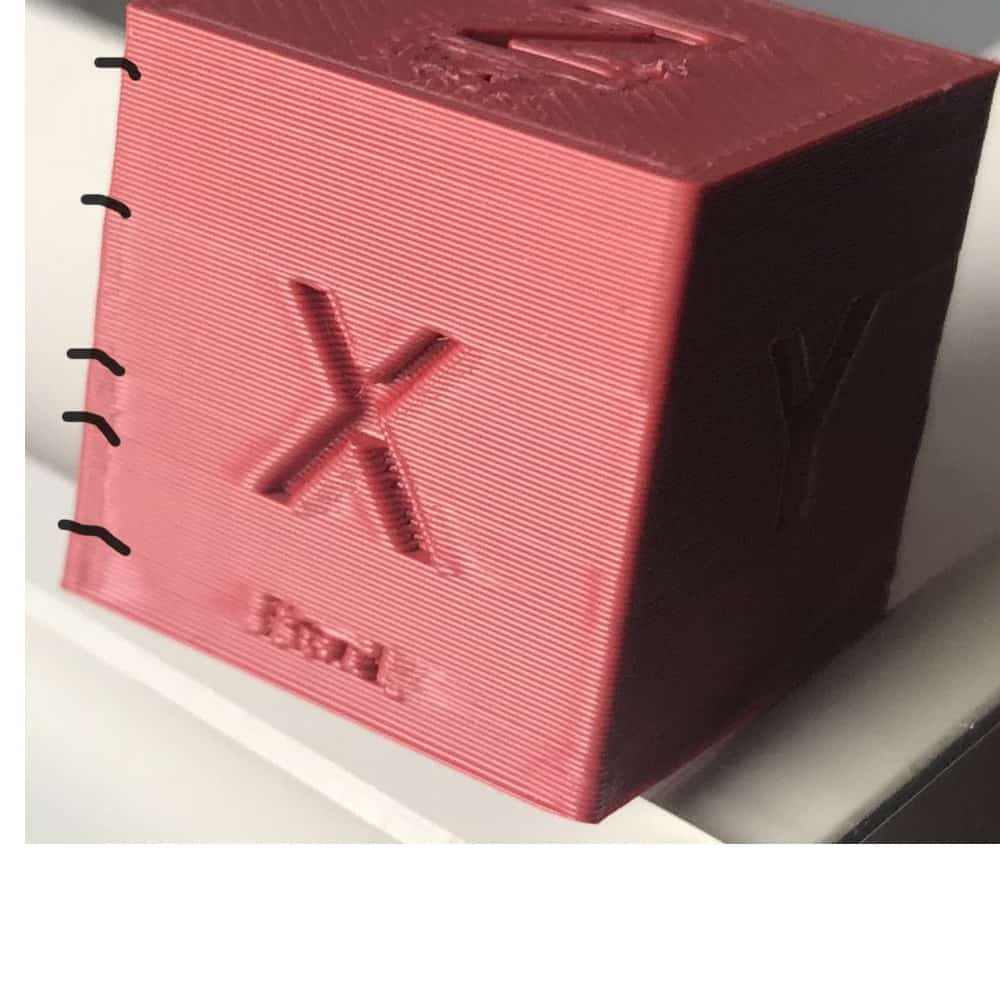

2. Improper Acceleration and Deceleration Settings

As the print head slows down to make turns, the printer may overcompensate by depositing extra filament. This effect, known as corner ringing, can manifest as bulges if the acceleration settings are too high or inconsistent.

3. Overextrusion

If the printer is extruding more filament than required, bulging corners become a common side effect. Overextrusion causes a surplus of material, which is particularly noticeable at corner transitions.

4. Material Properties

Different filaments like PLA, ABS, and PETG have unique thermal and flow characteristics. Some materials are more prone to bulging corners due to their tendency to remain soft and pliable longer, especially under excessive heat.

5. Inadequate Cooling

Insufficient cooling exacerbates the problem as the material takes longer to solidify, allowing it to deform under its own weight or due to the heat from subsequent layers.

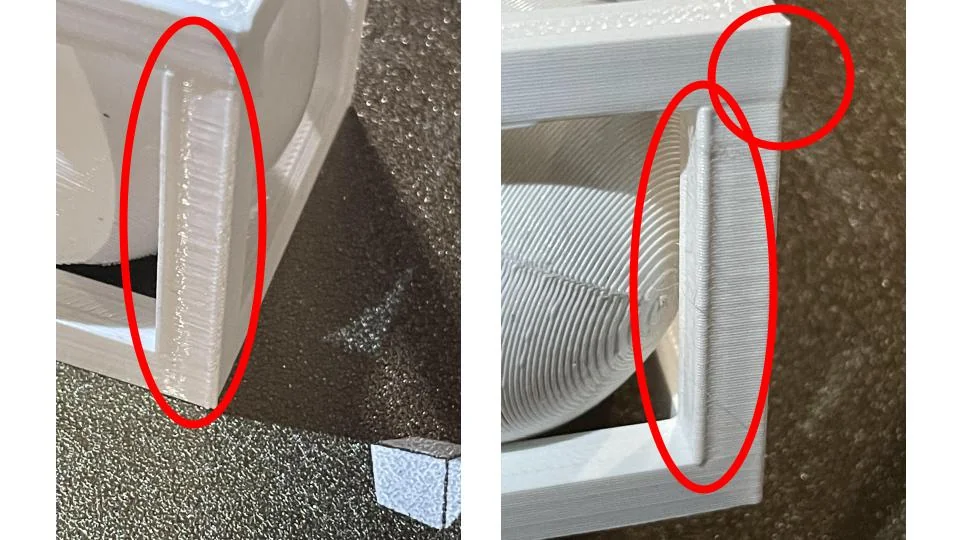

Example of a Common Flaw – Enhance Cooling Setup!

Here are two common examples of flaws where corner bulging can occur during 3D printing:

Situation 1: A Bulged Corner at the Start and End Point

In this situation, bulging occurs at the start and end of a print layer, typically due to excess filament being deposited when the nozzle starts or finishes its movement.

This can result from incorrect retraction settings, high printing speeds, or poor cooling, leading to the corners becoming rounded or swollen.

Situation 2: Corners without Start and End Point

In this case, corner bulges appear even when there’s no clear start or end point. This can be caused by factors like uneven extrusion, excessive print speed, or a lack of cooling.

The issue usually happens when the printer doesn’t have enough time to adjust during turns, causing the material to build up and deform the corners.

Strategies for Eliminating 3D Print Bulging Corners – Achieve Smooth Edges!

To achieve sharper corners and improve overall print quality, consider implementing the following strategies:

1. Calibration Adjustments:

- Extruder Calibration: Ensure that the extruder steps are correctly calibrated to prevent overextrusion. Adjusting pressure advance settings can help minimize oozing during direction changes.

- Bed Leveling: Use methods like mesh leveling or automatic bed leveling to maintain a flat print surface, which is crucial for accurate prints.

2. Optimize Print Speeds:

- Experiment with slower print speeds, particularly at corners, to allow for better material control and reduce overextrusion.

- Adjust jerk and acceleration settings to minimize speed changes at corners, which can help maintain consistent extrusion pressure.

3. Design Modifications:

- Incorporate chamfers or fillets on sharp corners in your model design. This modification reduces stress concentration and enhances print quality.

- Choose optimal print orientations to minimize overhangs and support needs, distributing stress more evenly during printing.

4. Material Considerations:

- Materials like PLA, ABS, and PETG behave differently, with ABS prone to warping and bulging corners.

- Correct temperature and flow rate settings prevent excess filament flow and overextrusion, reducing corner bulges.

Design Tips to Prevent 3D Print Bulging – Add Proper Support!

Here are some design tips to help prevent 3D print bulging, starting with the importance of proper support:

- Use Rounded Corners: Avoid sharp corners in your design, as they can cause excessive pressure and material buildup. Opt for rounded or filleted corners to reduce stress.

- Increase Wall Thickness: Thicker outer walls help maintain structural integrity and reduce the chances of bulging, especially during the printing of corners.

- Adjust Layer Height: Use a smaller layer height for more precise printing, reducing the risk of excess material being deposited at corners.

- Optimize Infill Settings: Lower infill density or adjust patterns to ensure even material distribution and prevent uneven pressure on corners.

- Design with Proper Support: Include built-in support structures or adjust the design for better stability during printing, helping to prevent warping or bulging issues.

Advanced Solutions for Persistent 3D Print Bulging Issues – Upgrade Your Filament!

Here are some advanced solutions to help tackle persistent 3D print bulging corners:

- Fine-tune Retraction Settings: Adjust retraction distance and speed to prevent excess filament from oozing out during printing, which causes bulging.

- Lower Print Speed: Slow down the printing speed, especially at corners, to give the printer more time to lay down material evenly.

- Optimize Cooling: Use cooling fans to control the temperature and prevent the material from warping or bulging as it cools.

- Increase Bed Adhesion: Ensure good adhesion by using a heated bed, glue stick, or painter’s tape to keep the print from lifting and causing bulges.

- Use Higher-Quality Filament: Choose high-quality filament that flows smoothly and is less prone to warping or creating inconsistent prints.

Read Also: 3d Printer Blobs On First Layer – The Guide Of 2024!

Frequently Asked Questions

1. How do I prevent warping and corner bulges?

To prevent warping, ensure proper bed adhesion using a heated bed or adhesives like glue stick. Adjust your cooling fan and retraction settings to prevent the material from lifting and causing bulging corners.

2. What print settings should I adjust to fix bulging?

Adjust retraction settings, lower print speed, and optimize cooling settings. Reducing the speed at corners and ensuring proper bed adhesion will also help reduce bulging and improve the overall print quality.

3. Why is my 3D print blobbing on the corner?

Blobbing occurs due to excess filament from improper retraction or high extrusion speed. To fix it, reduce the extrusion multiplier, adjust retraction distance, and lower print speeds. Better cooling also helps by solidifying the filament faster.

4. How to get rid of bulging corners in 3D printing?

To fix bulging corners, adjust print speed, cooling, and retraction settings. Slow down at sharp corners, use cooling fans, and fine-tune retraction to prevent excess filament. A heated bed can also help improve adhesion and reduce warping.

5. How do I improve print adhesion to prevent bulging?

Use a heated bed and adhesives such as glue stick or painter’s tape to improve adhesion. Proper bed leveling and ensuring the first layer sticks well can prevent bulging caused by lifting corners.

6. Should I reduce print speed for better results?

Yes, slowing down print speed, especially at corners, allows the printer more control over material deposition, helping to avoid excess filament and reducing bulging at corners.

7. Is cooling important for preventing bulging?

Cooling is essential. Using a cooling fan or adjusting the cooling settings prevents material from cooling too quickly and warping, which can cause corner bulging and other print imperfections.

8. How can I prevent corner bulging without changing my printer?

You can adjust your slicing settings by fine-tuning retraction, lowering speed, and optimizing cooling. Adding supports or changing the design to reduce sharp corners also helps prevent bulging.

9. What are the best materials to avoid bulging corners?

PLA is often a good choice for preventing corner bulging as it has lower warping tendencies compared to ABS or PETG. If you must use other materials, ensure proper temperature and cooling control to minimize bulging.

10. Can using a different slicer fix bulging corners?

Yes, different slicers offer various settings that can help fix bulging corners. By adjusting retraction, speed, and cooling settings, you can get better control over material flow, reducing corner bulging.

Conclusion

In conclusion, preventing and fixing bulging corners in 3D prints requires careful adjustments to retraction settings, print speed, cooling, and bed adhesion. Choosing the right material and ensuring proper bed leveling are also key factors in achieving smooth, accurate prints. By optimizing these aspects, you can significantly reduce common issues like corner bulging. With patience and fine-tuning, you can improve your 3D print quality and create flawless, professional-looking prints every time.