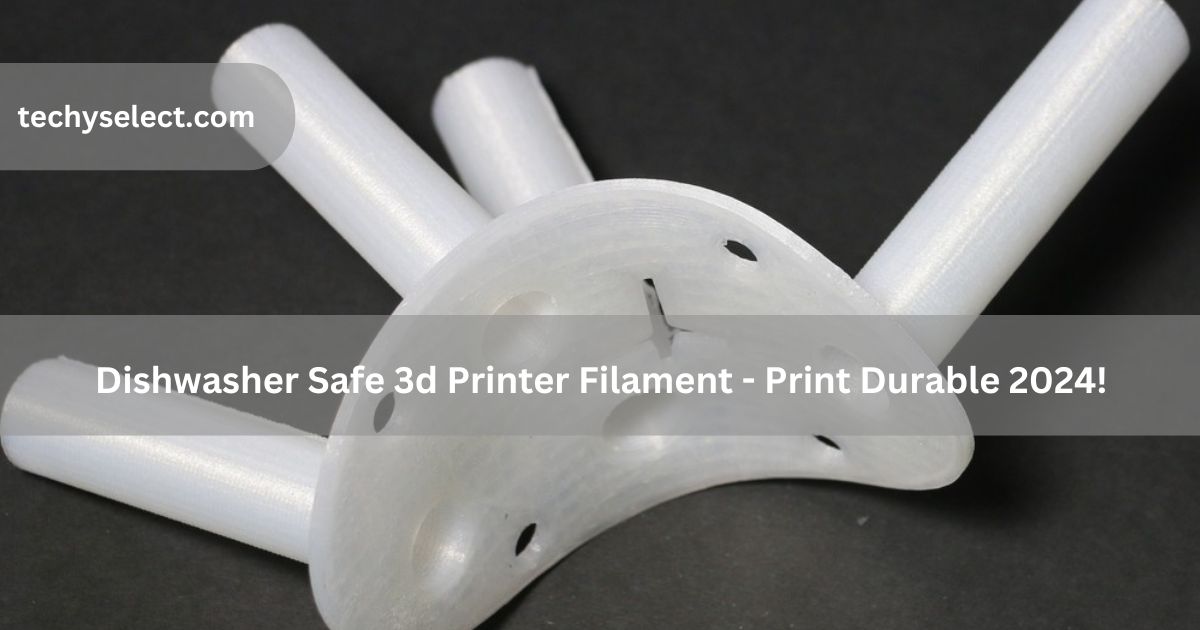

When I found dishwasher-safe 3D printer filament, it changed how I print. Now, I easily make strong kitchen tools and containers that survive washing. Picking the right filament ensures heat and water resistance, making prints last longer!

Dishwasher-safe 3D printer filament ( short answer )

Dishwasher-safe 3D printer filament is a material designed to handle heat, water, and detergents. It’s ideal for creating durable kitchen tools and containers that can be washed easily. Choose high-quality filaments for long-lasting, reusable, and functional 3D-printed items.

In this article we will discuss dishwasher safe 3d printer filament

What is dishwasher safe 3d printer filament?

Dishwasher-safe 3D printer filament is a special material made to handle heat, water, and detergents. It’s perfect for creating reusable kitchen tools, containers, and items that need regular cleaning.

To get the best results, use high-quality filaments and check if they are labeled dishwasher safe. This type of filament makes it easy to print durable and practical objects for everyday use.

How does the print quality affect dishwasher safety?

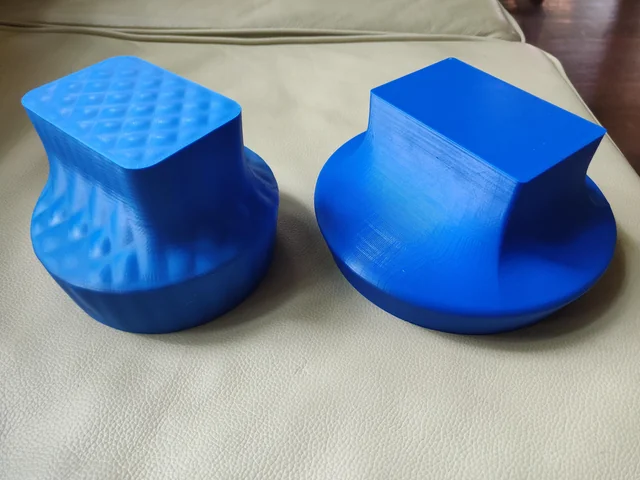

The print quality plays a big role in dishwasher safety. If the print has rough layers or gaps, water and heat can cause it to wear down faster. A smooth, well-printed object with tight layers will hold up better in the dishwasher.

Proper layer adhesion and good resolution help create stronger prints that resist damage from high heat and water pressure. Always aim for high-quality prints to ensure your 3D-printed items are durable and dishwasher safe.

What Filament material to use for dishwasher repair – Print Heat-Resistant!

Filament Materials for Dishwasher Repair:

- PETG (Polyethylene Terephthalate Glycol): PETG is durable, heat-resistant, and food-safe, making it ideal for dishwasher repairs like racks or clips.

- ABS (Acrylonitrile Butadiene Styrene): It is strong and withstands high temperatures, suitable for dishwasher parts exposed to heat, though it’s not always food safe.

- Nylon: This is highly durable, flexible, and resistant to wear, making it great for functional dishwasher components like hinges or seals.

- Polycarbonate (PC): Polycarbonate is extremely strong and heat-resistant, perfect for parts that require high durability and exposure to hot water.

- PP (Polypropylene): PP is lightweight, chemical-resistant, and dishwasher safe, ideal for parts like trays or handles in direct contact with water.

What Does Food Safe Really Mean – Choose Safe Materials!

Food safe means a material is safe to use with food and won’t harm you when it touches what you eat or drink. For 3D printing, food-safe filaments like PETG or PLA must meet safety standards and not release harmful chemicals.

However, the printing process can add tiny gaps or impurities where bacteria might grow. To make 3D-printed items truly food-safe, you might need to coat them with a food-safe sealant. Always check if the filament and process meet food safety guidelines before use.

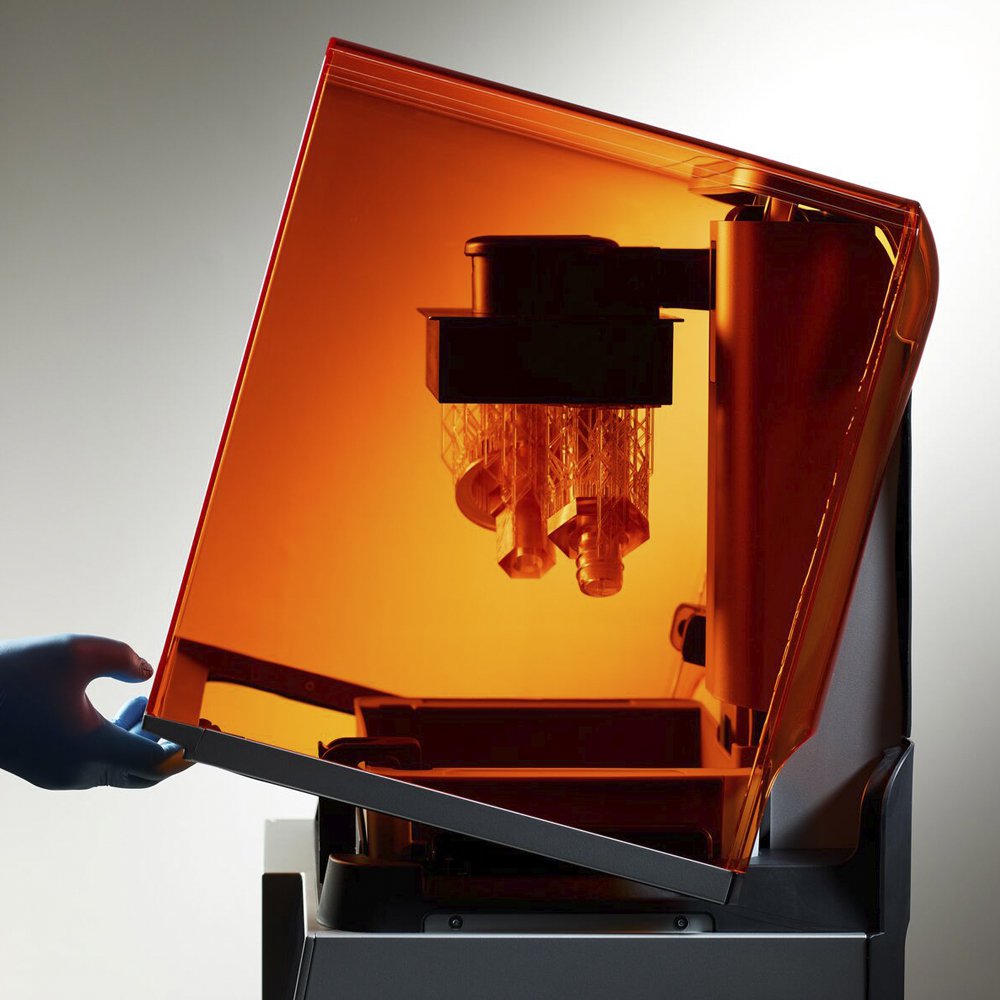

Food Safe 3D Printing With Stereolithography (SLA) – Use Certified Resins!

Food-safe 3D printing with Stereolithography (SLA) involves using a resin-based 3D printing method to create items that can safely come in contact with food. SLA provides high precision, making it great for detailed objects like cups or utensils.

However, the resin must be food safe, and post-processing is essential to smooth out the surface and remove any harmful chemicals. Always use certified food-safe resins and apply a food-safe coating to ensure your printed items are safe for kitchen use.

Food Safe 3D Printing With Fused Deposition Modeling (FDM) – Food-Safe Success!

Food-safe 3D printing with Fused Deposition Modeling (FDM) uses plastic filaments like PLA or PETG to create items for food use. To ensure safety, choose certified food-safe filaments and keep the printer clean to avoid contamination.

FDM prints often have small gaps where bacteria can grow, so applying a food-safe sealant is important. Proper nozzle temperature and smooth layer bonding also help improve safety. With the right materials and steps, FDM can create durable and dishwasher-safe kitchen tools.

Food Safe 3D Printing With Selective Laser Sintering (SLS) – Choose SLS Precision!

Food-safe 3D printing with Selective Laser Sintering (SLS) involves using powdered materials like nylon to create items layer by layer. SLS prints are strong but often have rough surfaces that can trap bacteria. To make them food safe, use certified materials and smooth the surface through sanding or coating.

Always clean the printer to avoid contamination. Post-processing with food-safe sealants ensures the item is safe for food contact. With the right steps, SLS is great for durable food-safe objects.

Are there any specific coatings that can make 3D printed parts dishwasher safe?

Yes, specific coatings can make 3D printed parts dishwasher safe. Food-safe epoxy coatings are popular because they seal gaps and protect the surface from water and heat. Silicone-based sealants are another good option, as they are flexible and heat-resistant.

For PLA prints, a thin layer of polyurethane can provide protection but check for food safety certifications. Always ensure the coating is evenly applied and fully cured before use to keep the part safe and durable in the dishwasher.

What are the risks of using 3D printed parts in a dishwasher?

1. Heat Damage

Some 3D printed materials, like PLA, can’t handle the high temperatures in a dishwasher. Exposure to heat can cause these prints to warp, bend, or lose their shape. This makes them unsuitable for long-term use in dishwashers, especially on high heat settings.

2. Water Absorption

Materials like Nylon can absorb water, which can weaken their structure over time. This makes the 3D printed parts more likely to break or become deformed after multiple dishwasher cycles, reducing their lifespan and performance.

3. Bacteria Growth

The layer lines on 3D prints can trap food particles, creating small pockets where bacteria can grow. These hard-to-clean areas may make it difficult to keep the part sanitary, especially in items like kitchen utensils or containers.

4. Chemical Damage

Dishwasher detergents contain chemicals that can damage 3D printed parts over time. Some materials or coatings may degrade with repeated exposure, affecting the surface quality and strength of the print. It’s essential to use food-safe coatings to protect against this.

5. Loss of Strength

Repeated exposure to heat and moisture in a dishwasher can cause 3D printed parts to lose their strength. Over time, materials may become brittle and less durable, making the parts prone to breaking or cracking during use.

How can I ensure my 3D printed parts remain food safe over time?

To ensure your 3D printed parts remain food safe over time, start by using food-safe filaments like PETG or nylon. Apply a food-safe coating, such as epoxy or silicone, to seal the print and prevent bacteria buildup.

Regularly clean your prints to avoid contamination, especially in areas with visible layer lines. Also, avoid exposing prints to high temperatures or harsh chemicals, as this can degrade the material and coating. Always check for wear and tear and replace parts as needed.

General Food-Safe 3D Printing Considerations – Safe Kitchen Creations!

1. Choose Food-Safe Filaments

Pick filaments like PETG, PLA, or FDA-approved materials designed for food contact. Not all 3D printing materials are safe, so check the manufacturer’s specifications. Choosing certified food-safe filaments ensures your printed items won’t release harmful chemicals.

2. Avoid Contamination During Printing

Keep your printer’s nozzle, bed, and environment clean to prevent dirt or leftover material from contaminating prints. Contamination during the printing process can make items unsafe for food use. Regular cleaning and maintenance are key for food-safe projects.

3. Seal the Surface

3D-printed items often have small gaps that can trap bacteria, making them unsafe for food. Applying a food-safe coating, such as resin or sealant, smooths out these gaps. This step improves safety and durability, especially for reusable kitchen items.

4. Use a Dedicated Printer

Printers used for non-food-safe materials or chemicals might leave harmful residues. Using a separate printer for food-safe projects ensures there’s no risk of cross-contamination. This practice is especially important for consistent food safety in long-term use.

5. Verify Material Safety

Always verify that the filament meets food safety standards before use. Some materials release harmful chemicals under heat or pressure, which could contaminate food. Checking certifications ensures the safety of your 3D-printed items for direct food contact.

Read Also: Edible 3d Printer Filament – Transform Food Ideas!

Frequently Asked Questions

1. Can I use 3D printed parts for food storage in a dishwasher?

Yes, 3D printed parts made from dishwasher-safe materials like PETG can be used for food storage. Make sure the print is sealed and has a smooth surface to avoid contamination and bacterial growth.

2. How can I check if my 3D print is dishwasher-safe?

Check the material’s specifications first. Filaments like PETG, Nylon, or certain resins are dishwasher-safe. You can also apply a food-safe coating to increase durability. Testing by washing a small part is another good way to confirm.

3. Can I use 3D prints for dishware like plates or cups?

Yes, you can use 3D prints for dishware if they are made from dishwasher-safe materials like PETG or Nylon. Be sure that the parts are smooth, well-sealed, and food-safe before using them for holding food or liquids.

4. Does coating my 3D print make it safe for food?

Yes, food-safe coatings like epoxy or polyurethane can make your 3D print safe for food contact. These coatings help seal the surface, prevent bacteria buildup, and make it easier to clean, ensuring safety and durability.

5. Can 3D printed parts become food-safe after printing?

Yes, applying a food-safe coating to your 3D prints can make them safe for food contact after printing. These coatings help prevent contamination by sealing the print and creating a smooth surface for easy cleaning.

6. How do I avoid warping when using 3D prints in the dishwasher?

To avoid warping, use materials like PETG or Nylon, which have better heat resistance. Ensure your 3D prints are properly sealed and finished to maintain their shape. Lower the dishwasher’s heat settings for delicate prints.

7. How does material choice affect 3D printed part strength?

The material choice affects the strength of 3D printed parts. Heat-resistant materials like PETG are stronger and more durable under dishwasher conditions compared to PLA. Always choose materials designed to handle heat, moisture, and detergents.

8. Can I use PLA for dishwasher-safe prints?

No, PLA is not recommended for dishwasher-safe prints as it can warp under high temperatures. PLA has a low melting point and does not withstand heat or water exposure well. For dishwasher-safe prints, opt for materials like PETG or Nylon.

9. What is the effect of dishwasher cycles on 3D prints?

Dishwasher cycles can expose prints to high heat and water pressure. Materials that aren’t designed to withstand these conditions, like PLA, can degrade or warp. Choosing the right filament ensures longevity even after multiple cycles.

10. Are there any post-processing techniques to make 3D prints more dishwasher-resistant?

Yes, post-processing techniques like sealing the print with food-safe coatings or adding a layer of heat-resistant paint can make 3D prints more resistant to dishwasher conditions. These steps can help protect the print from wear and tear caused by heat and water exposure.

Conclusion

In conclusion, choosing dishwasher-safe 3D printer filament, like PETG or coated materials, ensures your prints handle heat and water pressure. Smooth, high-quality prints are key to durability. Adding food-safe coatings provides extra protection and safety. Regular cleaning and inspection keep your 3D-printed parts long-lasting and functional. By using the right materials and techniques, you can confidently create dishwasher-safe items. This approach combines convenience with reliability for everyday use.

Read More: