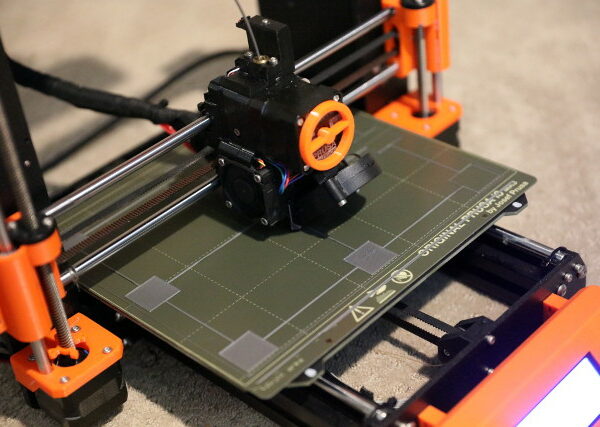

I know how frustrating it is when a 3D printer stops halfway through. It happened to me too! Often, it’s small issues like filament jams or temperature problems. I’ll share simple tips to help avoid this problem.

why does my 3d printer stop printing halfway through( short answer )

A 3D printer may stop printing halfway due to filament jams, temperature fluctuations, or power interruptions. Check for proper filament flow, stable temperatures, and secure connections. Regular maintenance helps prevent unexpected print interruptions and ensures smoother results.

In this article we will discuss why does my 3d printer stop printing halfway through.

Why Does My 3D Printer Stop Printing Halfway Through?

A 3D printer might stop halfway through for several reasons. Common causes include filament running out, getting tangled, or a jam in the nozzle. Temperature issues, like the printer overheating or cooling too much, can also cause problems.

Sometimes, power interruptions or loose connections might stop the printer. To fix this, make sure the filament is loaded correctly, keep the printer clean, and check for stable temperatures. Regular maintenance and proper setup can help avoid these frustrating interruptions.

What Does It Look Like When My 3D Printer Stops Printing Halfway Through?

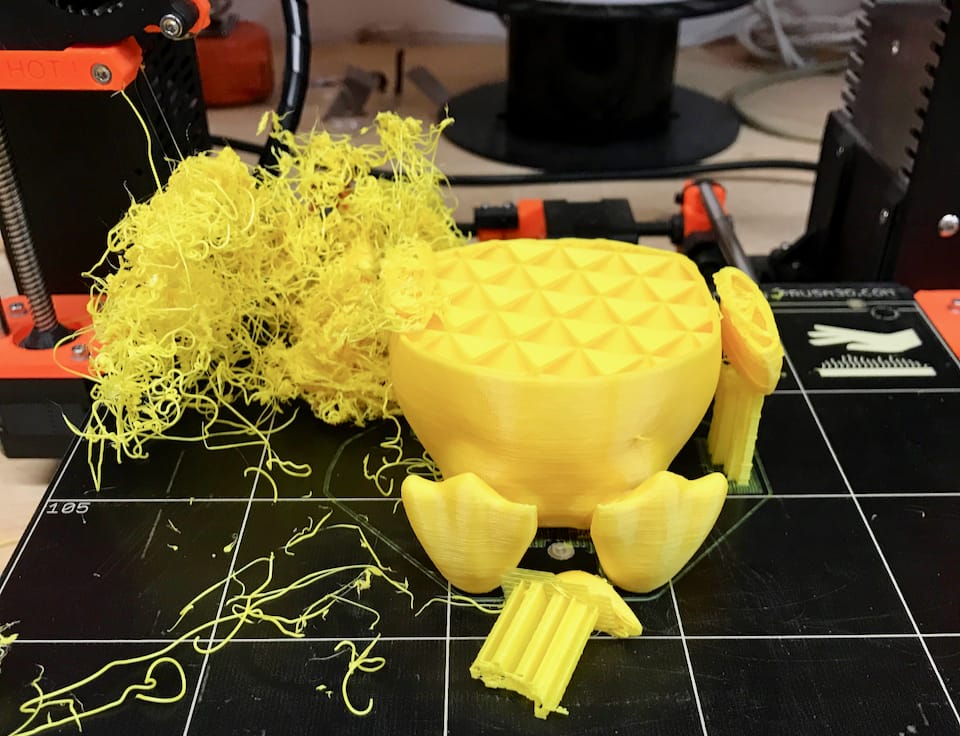

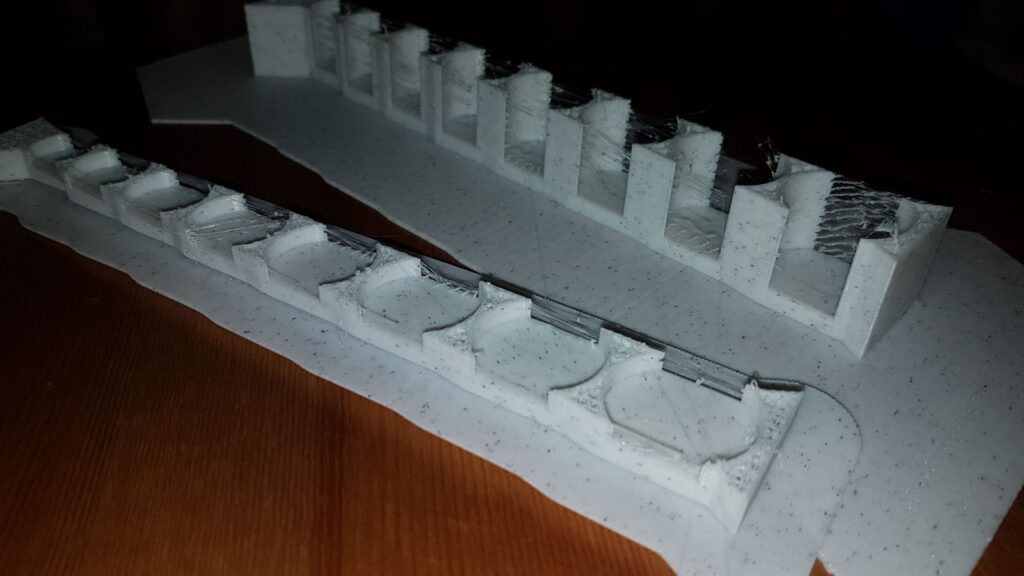

When a 3D printer stops printing halfway through, it often leaves the print unfinished with a flat or incomplete top layer. The printer may stop moving, the nozzle might stay idle, or the filament could stop extruding. Sometimes, the print bed remains heated, but no further progress is made.

You might also notice filament tangles, jams, or temperature warnings on the printer’s display. Identifying these signs helps troubleshoot the issue and get your printer back to completing projects smoothly.

What Are the Most Common Causes of a 3D Printer Stopping Halfway Through?

A 3D printer stopping midway through a print can be frustrating, but understanding the common causes can help you address the issue quickly.

- Filament Problems: Tangled or low-quality filament can jam the extruder or run out unexpectedly.

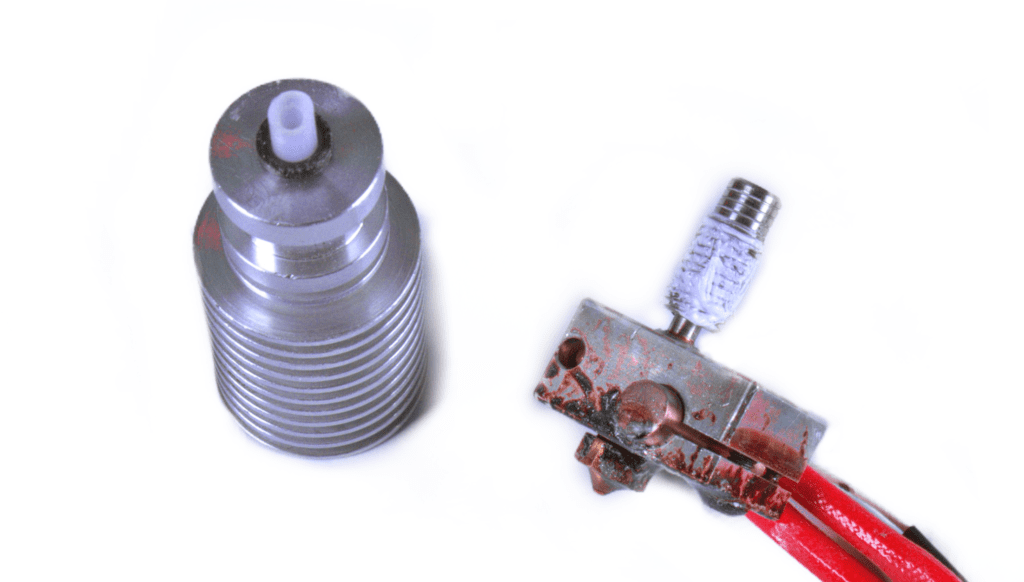

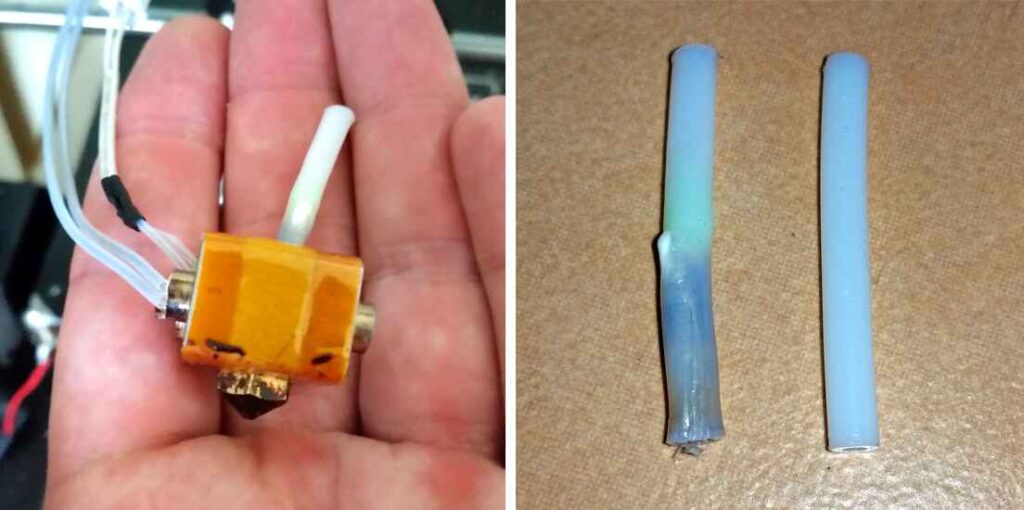

- Nozzle Clogs: Debris or hardened filament in the nozzle can block extrusion.

- Temperature Fluctuations: Inconsistent hotend or bed temperatures can disrupt the printing process.

- Power Issues: Unstable power supply or sudden outages can halt the printer.

- Mechanical Failures: Worn belts, motors, or other parts may lead to incomplete prints.

- Software Errors: Incorrect slicing settings or outdated firmware can cause interruptions.

- Identifying and resolving these issues can help ensure successful, uninterrupted 3D printing.

Why Does Extrusion Stop Halfway Through the Printing Process?

Several factors can cause extrusion to stop halfway through the printing process. It’s essential to check various components of the printer to identify and fix the issue. These are some common causes to look into:

1. Incorrect Slicing Settings

Improper slicing settings, such as low extrusion rate or incorrect layer height, can cause the printer to under-extrude or stop extruding mid-print. Double-check the settings in your slicer software, especially the flow rate and layer height, to ensure they match the material and print requirements.

2. Bad Quality Filament

Low-quality filament may have inconsistent thickness or impurities that prevent smooth extrusion. This can lead to clogs or gaps in extrusion. Use high-quality filament and store it properly to avoid moisture absorption, which can also affect print quality and filament flow.

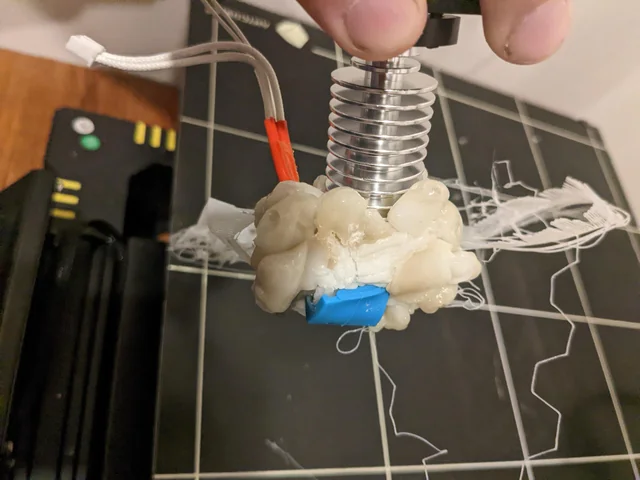

3. Overheated Extruder or Hotend

When the extruder or hotend overheats, it can cause the filament to burn or degrade, leading to inconsistent extrusion. Monitor the temperature during printing and ensure the cooling system is functioning properly to maintain a stable hotend temperature throughout the process.

4. Extruder Gear Slippage

Worn or loose extruder gears can slip on the filament, preventing proper feeding and causing extrusion failure. Regularly inspect the extruder gears for wear and make sure they’re properly tightened. Replacing worn gears can restore smooth filament flow and extrusion performance.

5. Blockages in the PTFE Tube

If the PTFE tube connecting the extruder to the hotend is clogged or kinked, it may restrict filament flow. Inspect the tube regularly for blockages or signs of wear, and replace it if necessary to maintain consistent extrusion.

6. Improper Print Bed Leveling

An uneven print bed can affect the first few layers, causing issues with extrusion. If the bed is too far from the nozzle, the filament may not adhere properly. Ensure the print bed is level and calibrated before starting a new print to avoid extrusion issues.

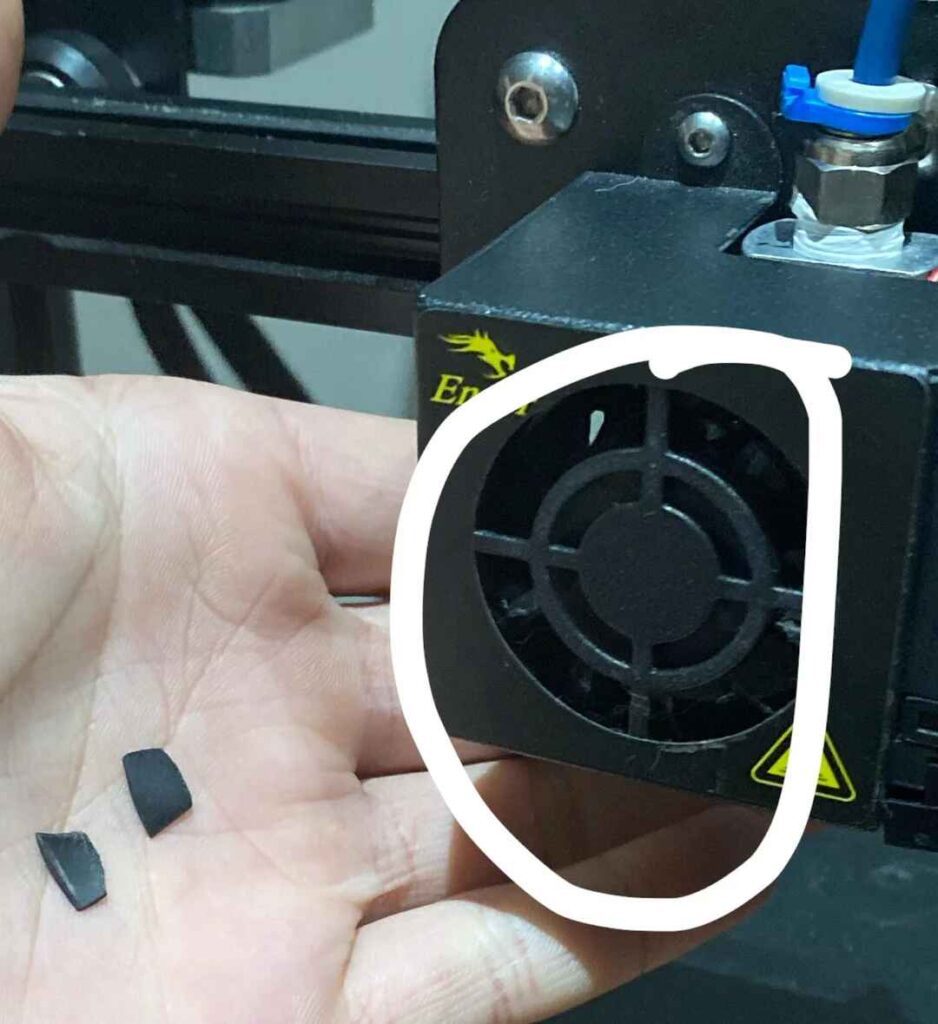

7. Cold End Cooling Fan Failure

If the cold end fan fails, the extruder may overheat, which can lead to inconsistent filament flow or extrusion stops. Check the cooling fan regularly, especially if you notice extrusion problems, and replace it if necessary to ensure proper cooling of the cold end.

8. Poor Extruder Calibration

If your extruder is improperly calibrated, it can lead to issues with filament feeding. Incorrect steps per millimeter or under-extrusion can stop the filament from flowing correctly. Perform regular calibration checks on the extruder to ensure it’s working within the correct specifications.

How Do Print Settings Affect My 3D Printer Stopping Halfway Through?

Print settings are essential for the smooth operation of your 3D printer. Incorrect configurations can result in extrusion issues, causing the print to stop halfway through. Below are some key settings to review and adjust:

- Incorrect Layer Height: Setting the layer height too high can cause poor extrusion, leading to incomplete prints.

- Low Extrusion Multiplier: If the extrusion multiplier is set too low, the printer may not feed enough filament, causing stoppages.

- Wrong Print Speed: High print speeds can strain the extruder, causing it to fail halfway through the print.

- Improper Retraction Settings: Incorrect retraction settings can lead to filament jams or clogs in the nozzle.

- Inconsistent Flow Rate: An inconsistent flow rate can cause gaps or interruptions in the extrusion process.

- Unsupported Slicing Parameters: Using unsupported or incorrect slicing parameters can result in printing errors or incomplete layers.

Making sure these settings are right can help prevent interruptions and ensure your 3D prints come out looking their best. Adjusting them properly can make a big difference in the smoothness and success of your printing process.

Read Also: What Does Fdw Mean On Hp Printer – Simplify Printing!

How to Fix a 3D Printer That Stops Printing Halfway Through?

If your 3D printer keeps stopping halfway through a print, don’t worry—you’re not alone. This is a common problem with several possible causes, but the good news is that most of them are easy to fix. Try these solutions to get your printer running smoothly again:

1. Check the Filament Flow

Ensure your filament isn’t tangled, running out, or improperly loaded. Examine the nozzle for clogs and clean it if necessary. Always use high-quality filament and maintain proper spool tension for smooth, uninterrupted printing.

2. Monitor Temperature Stability

Confirm the nozzle and print bed temperatures remain stable during printing. Sudden temperature drops or overheating can cause interruptions. Check your printer’s temperature settings and ensure the heating elements are functioning properly to prevent these issues.

3. Inspect Connections and Power Supply

Loose cables or power interruptions can stop your printer. Secure all connections and use a reliable power source. Consider a UPS (uninterruptible power supply) to protect against unexpected outages and ensure a continuous print.

4. Update Firmware and Software

Outdated firmware or slicing software can cause printing errors. Regularly update your printer’s firmware and slicing program to the latest versions. Updated software ensures compatibility and fixes bugs that might lead to print halts.

5. Perform Regular Maintenance

A well-maintained printer performs better. Clean the nozzle, print bed, and other components regularly. Lubricate moving parts like rods and bearings, and inspect belts for proper tension to avoid mechanical failures during a print.

What Are Common Solutions for a 3D Printer Stopping Halfway Through?

When your 3D printer stops printing halfway through, there are practical solutions to resolve the issue and prevent it from happening again:

- Check and Replace Filament: Ensure the filament is properly loaded, untangled, and of good quality.

- Clean the Nozzle: Remove any clogs or debris to restore smooth filament flow.

- Calibrate Temperature Settings: Maintain consistent hotend and bed temperatures suited for your material.

- Secure Power Supply: Use a reliable power source and consider adding a backup power unit.

- Update Firmware and Software: Keep your slicing software and printer firmware up to date for optimal performance.

- Inspect Moving Parts: Regularly check belts, motors, and gears for wear or looseness.

These steps can help you troubleshoot and prevent future interruptions, ensuring successful prints.

Read Also: What Is The Purpose Of A 3d Printer – Innovate Faster!

Frequently Asked Questions

1. Why does my 3D printer keep stopping in the middle of printing?

Your printer may stop due to filament issues, like tangles or running out of material, a clogged nozzle, or mechanical failures. Power interruptions or software errors can also cause prints to stop unexpectedly. Regular maintenance often resolves these problems.

2. Why do 3D prints fail halfway through?

3D prints fail halfway through due to issues like nozzle clogs, inconsistent temperatures, or filament jams. Mechanical failures, such as worn belts or motors, can also disrupt the print. Proper calibration and regular upkeep help prevent these issues.

3. Why does my printer stop in the middle of printing?

A printer can stop mid-print due to unstable power supply, incorrect slicing settings, or blockages in the extruder. Firmware bugs or outdated software might also be to blame. Ensuring optimal settings and equipment conditions minimizes such interruptions.

4. Why is my 3D printer not printing in the middle?

If your printer stops printing mid-process, check for filament tangles, nozzle blockages, or feed mechanism issues. Overheating or fluctuating temperatures might also disrupt extrusion. Addressing these factors ensures smoother, uninterrupted prints.

5. Does filament moisture cause printing problems?

Yes, filament moisture can cause printing problems. When filament absorbs moisture, it can swell, bubble, or become brittle, leading to clogs or inconsistent extrusion. Storing filament in a dry box or sealed bag prevents these issues.

6. How can I prevent my 3D printer from stopping mid-print?

Yes, Regular maintenance, using high-quality filament, and ensuring your print bed and extruder are calibrated can prevent stoppages. Additionally, using reliable power sources and monitoring temperature settings ensures uninterrupted prints.

7. What are the signs of a clogged nozzle in a 3D printer?

Yes, Signs of a clogged nozzle include inconsistent extrusion, stringy prints, or the filament not coming out properly. If your print quality decreases or the nozzle is making unusual sounds, it might be clogged.

8. How do thermal cutoffs affect 3D printing?

Yes, Thermal cutoffs are safety features that stop the printer if it detects overheating, preventing damage or fire. However, if they malfunction or trigger unnecessarily, they can stop the print midway. Keeping the hotend and bed temperatures properly calibrated can avoid this.

9. What are the best practices for maintaining a 3D printer’s extruder?

Yes, Regularly clean the extruder, lubricate moving parts, and check for worn-out components. Ensure the filament feeds smoothly and the gears are aligned correctly. This helps prevent clogs and ensures consistent extrusion during prints.

10. How can I install a filament sensor on my 3D printer?

Yes, Installing a filament sensor typically involves connecting the sensor to the printer’s mainboard and calibrating it in the software. This sensor can detect when filament runs out or tangles, pausing the print to prevent failure.

Conclusion

In conclusion, Dealing with a 3D printer that stops halfway through can be frustrating, but most issues have simple fixes. Regular maintenance, high-quality filament, and proper print settings go a long way in ensuring smooth prints. Don’t forget to check for nozzle clogs and keep your printer calibrated. With a bit of care and attention, you can avoid interruptions and enjoy successful, high-quality prints. Happy printing, and remembering every problem is a chance to learn and improve.

Read More: