I once had the same problem! My 3D printer printed the object backward. It turned out there were a few reasons for this, like motor wires or wrong settings. In this guide, I’ll show you how to fix it!

why is stl files printing in reverse ( short answer )

STL files may print in reverse if the printer’s motor wires are wrong, or if the X and Y axes are mixed up. It can also happen due to wrong settings in the printer’s firmware. Adjust these to fix the problem.

In this article we will discuss why is stl files printing in reverse.

What Is An Stl File?

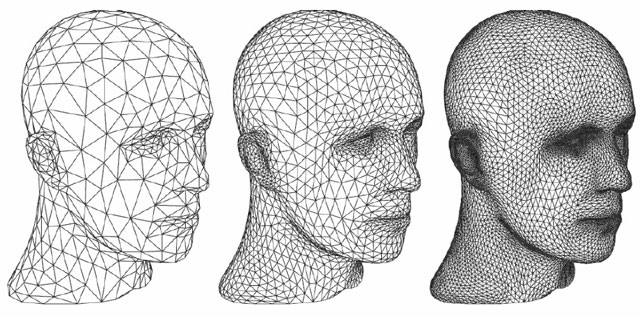

An STL file is a digital file used for 3D printing. It contains the shape of an object, divided into small triangles, which guide the printer to build it layer by layer. STL files only show the object’s shape, not its color or texture. They are commonly used in 3D printing.

Why Is My Printer Printing Everything Backwards?

If your 3D printer is printing everything backwards, it might be due to swapped X and Y axis settings, wrong motor wiring, outdated firmware, or incorrect slicing software settings. To fix it, check the axis settings, update firmware, properly orient the model, and recalibrate your printer.

Common Causes Of Reverse/Mirrored Printing In 3d Printing

Reverse or mirrored printing in 3D printing can occur due to the following reasons:

- Incorrect Axis Configuration: Swapping or misconfiguration the X and Y axes in the printer’s settings can lead to reversed prints.

- Motor Wiring Issues: Improperly connected motor wires for the X or Y axis can cause movements to be mirrored, resulting in reverse prints.

- Outdated Firmware: Using outdated firmware may result in misinterpretation of commands, causing mirrored or reversed prints.

- Incorrect Slicing Settings: If the model is flipped or mirrored in the slicing software, the printer will follow the incorrect orientation during printing.

- Calibration Errors: Poor calibration, such as incorrect bed leveling or axis alignment, can contribute to reversed printing.

By identifying and addressing these causes, you can prevent reverse or mirrored printing in 3D printers.

How To Identify The Problem With Your Stl File Orientation

To check if the STL file orientation is causing issues:

- Check in Slicing Software: Ensure the model is positioned correctly.

- Look for Mirroring or Flipping: Confirm the model isn’t flipped or mirrored.

- Preview the Print: Use the preview feature to check orientation.

- Check for Inverted Faces: Ensure the faces are not inverted.

- Review Printer Settings: Verify the printer’s orientation settings.

By following these steps, you can easily identify and correct any orientation issues with your STL file.

Can The Orientation Of The Stl File Affect The Printing Quality?

Yes, STL file orientation greatly affects 3D printing quality. Good orientation improves part strength, reduces support needs, and gives a smoother surface. It also saves printing time and material. Wrong orientation can weaken the model or make it less accurate. Use slicing software to test and set the best position for printing.

What Are Stl File Problems?

STL files are commonly used for 3D printing, but they can have issues that affect the quality of prints. Here are some common problems:

- Non-Manifold Edges: These are edges shared by more than two faces, causing confusion in slicing and errors during printing.

- Holes or Gaps in the Model: Missing surfaces can lead to incomplete or failed prints.

- Inverted Normals: Surface orientations might be flipped, causing errors in how the slicer interprets the model.

- Too Many Polygons: High-polygon models can slow down processing and may not be compatible with slicers.

- Scale and Size Errors: Models may be too large or too small, leading to print failures or misalignment on the build plate.

- Thin Walls: Walls thinner than the printer’s nozzle width can result in weak or incomplete structures.

- Unsupported Overhangs: Models with overhangs that lack proper support may print poorly or fail entirely.

Fixing STL Problems:

Use software like Meshmixer, Netfabb, or Blender to repair holes, adjust scaling, and fix inverted normals or non-manifold edges before printing.

Read Also: Why Is My Pantum Printer Not Printing – Fix Your Printer 2025!

Fixing The Problem Of Stl Files Printing In Reverse

If your 3D printer is printing STL files in reverse, here are some solutions to help you fix the problem:

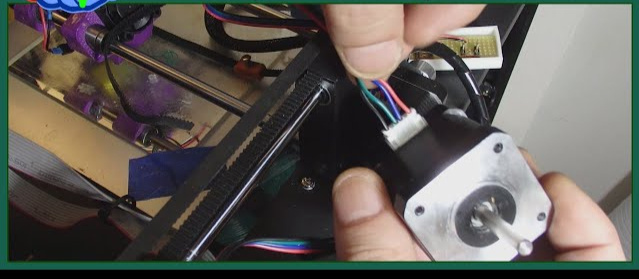

Solution 1: Rotate Motor Cables

Incorrect motor cable connections can cause reversed prints. Check the motor cables for the X and Y axes. If they are swapped or connected improperly, reconnect them correctly following your printer’s wiring diagram. This will ensure proper movement directions.

Solution 2: Switch X And Y Axes

Misconfigured X and Y axes in your printer’s settings can lead to mirrored or reversed prints. Review the axis settings in the printer’s control panel or software and ensure they are correctly assigned. This adjustment will correct the printing direction.

Solution 3: Adjust Firmware Settings

Outdated or misconfigured firmware can cause reversed printing. Visit the website of your printer’s manufacturer to download and update to the most recent firmware version. Updating the firmware often resolves unexpected behavior and ensures your printer operates correctly.

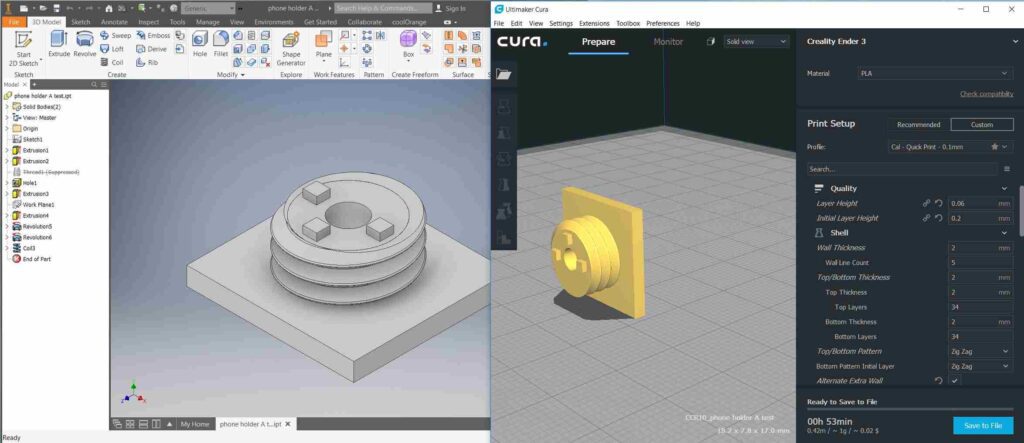

Solution 4: Adjust The Model In Slicing Software

Open the STL file in slicing software like Cura or PrusaSlicer. Check the model’s orientation. If it’s flipped or upside down, use the rotate tools to position it correctly. Preview the print to confirm that it will print in the right orientation.

Solution 5: Use Mirror Or Flip Tools In Slicing Software

If the issue persists, use the mirror or flip options in your slicing software. These tools allow you to manually adjust the model’s orientation to ensure it prints correctly.

Solution 6: Recalibrate Your Printer

Poor calibration, such as incorrect bed leveling or alignment, can cause misprints. Recalibrate your printer, paying attention to bed leveling and axis alignment. Proper calibration will ensure accurate printing.

By following these steps, you can easily fix STL files printing in reverse and get your prints looking as intended.

Tips To Prevent Stl Files From Printing In Reverse

- Design with Proper Orientation: Always save STL files with the correct orientation in your 3D modeling software.

- Preview Before Printing: Use the slicing software’s preview option to verify the model’s position before printing.

- Organize Motor Wiring During Setup: Double-check the motor cables during initial printer setup to avoid incorrect connections.

- Regularly Maintain Printer Settings: Periodically check and save axis settings to prevent unintentional changes.

- Choose Quality Software and Updates: Use reputable slicing software and keep your printer firmware updated to avoid configuration glitches.

These proactive steps help avoid reverse printing entirely.

Which Software Can Help Troubleshoot Stl File Printing Issues?

- Slicing Software: Cura and PrusaSlicer help check model orientation and layers.

- STL Repair Tools: Fix broken files with Meshmixer or Netfabb.

- Printer Software: Creality Slicer is great for Creality printers.

- Firmware Tools: Marlin and Klipper help check printer movements.

- 3D Modeling Software: Blender or Tinkercad fix design errors.

These tools make it easy to fix STL printing problems.

Read Also: What Printer Takes Ink Cartridge 951xl – Find Compatible Printers!

Frequently Asked Questions

1. Which Is Better, Obj Or Stl?

STL is more commonly used for 3D printing as it’s simple, widely supported, and focuses only on the shape of the model. OBJ files support additional features like color and texture but can be more complex and larger in size.

2. Can I Fix Reverse Printing With A Simple Software Reset?

Sometimes, a software reset or reconfiguration of the printer’s slicing settings may resolve the issue, but hardware issues should also be addressed.

3. Can A Corrupt Stl File Cause Reverse Printing?

Yes, a corrupt or incomplete STL file may cause unexpected print behavior, including reversed prints. Try repairing the file using STL repair tools.

4. What Is The Best Way To Prevent Reverse Printing In Future Prints?

Always verify the model orientation in slicing software, check motor wiring, and update firmware to prevent issues with reverse printing.

5. Can Reverse Prints Be Caused By Incompatible Software Versions?

Yes, outdated slicing software may not properly handle the model or printer settings, leading to reversed prints. Always use the latest version of your software.

6. What Role Does Printer Calibration Play In Reverse Printing?

Proper calibration, including bed leveling and axis alignment, is crucial to avoid reverse or mirrored prints. Incorrect calibration can cause alignment problems.

7. Is There A Specific Stl File Format That Avoids Reverse Printing?

No, STL is the most commonly used file format for 3D printing, but issues like reverse printing are usually related to the model’s orientation, printer settings, or firmware.

8. Should I Always Use The Latest Version Of My 3d Printer’s Firmware?

Yes, updating to the latest firmware ensures your printer runs smoothly and fixes potential bugs that may cause reverse printing.

9. Why Do 3d Printers Print Upside Down?

3D printers may print upside down due to incorrect model orientation in the slicing software, wrong bed leveling, or misconfiguration of the printer’s axes. Ensuring proper alignment and orientation of the model can prevent this issue.

10. Does Using A Different 3d Printer Affect Stl File Printing Orientation?

Yes, different printers might have different axis configurations or settings that can affect how the STL file is interpreted and printed.

Conclusion

In conclusion, reverse printing of STL files can result from various factors, such as incorrect axis settings, motor wiring issues, or misconfigured slicing software. By properly checking and adjusting these settings, updating firmware, and ensuring accurate model orientation, you can avoid these problems. Regular calibration and maintenance also help ensure consistent print quality.

Read More: